Table of Contents

- Understanding Paddle Blenders

- Key Benefits of Paddle Blenders

- Applications Across Industries

- Design Innovations in Paddle Blenders

- Choosing the Right Paddle Blender

- Maintenance and Safety Considerations

- Conclusion

Industrial manufacturing relies on precise mixing to ensure the quality and consistency of its products. Equipment like paddle blenders delivers the gentle yet thorough blending necessary across a broad spectrum of applications, from food to pharmaceuticals. These machines are crucial in handling various materials while preserving mix integrity. Their efficiency and versatility stem from a design that ensures controlled movement, supporting both sensitive and tough substances. Paddle blenders promote sustainability via energy savings and minimal product loss. Industries increasingly depend on such technology for performance and safety, making them a vital investment. Companies value blenders that perform well with minimal wear and gentle handling of ingredients. Selecting the right equipment enhances yield, throughput, and quality, providing long-term efficiency and cost benefits. Understanding features like material properties and sanitation helps manufacturers select suitable blenders to reduce processing time, conserve resources, and improve product quality while ensuring safety and compliance.

Understanding Paddle Blenders

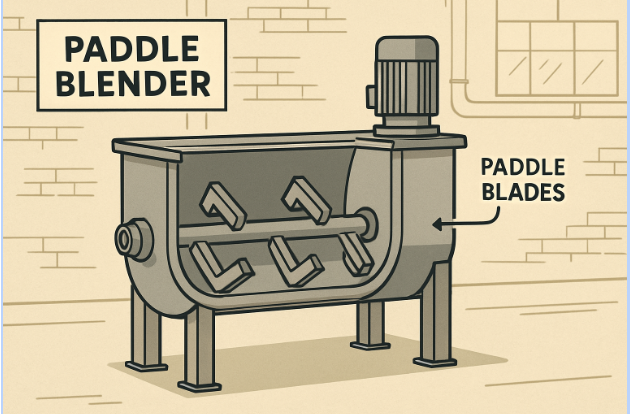

Paddle blenders are engineered with a U-shaped horizontal trough housing a central shaft. Attached to this shaft are paddle-shaped blades, precisely angled to move ingredients both radially and axially. These blades are set to ensure materials are swept and folded continuously, promoting a consistent and homogeneous blend even when dealing with disparities in ingredient size, density, or moisture.

This technology ensures a uniform and controlled distribution in a batch, minimizing excessive heat generation and product degradation. Whether processing powders, granules, or semi-solid substances, paddle blenders have consistently demonstrated their versatility and reliability in numerous production scenarios, distinguishing them from other industrial mixing solutions.

Key Benefits of Paddle Blenders

- Gentle Mixing Action: Paddle blenders employ a scooping and lifting motion, minimizing the breakdown of fragile ingredients and preserving the material’s characteristics throughout the process.

- Adaptability: Their design accommodates a wide range of textures, viscosities, and bulk densities, making them suitable for industries spanning from food processing to chemicals and pharmaceuticals.

- Energy Efficiency: Optimized blending mechanics result in lower power utilization, leading to reduced operational costs and a smaller carbon footprint. Innovative mixing technologies can significantly reduce energy consumption, leading to substantial cost savings and improved sustainability.

- Expedited Processing: Paddle blenders are engineered to mix even large batches, reducing processing times efficiently—ideal for high-throughput production environments.

Applications Across Industries

The dependable performance of paddle blenders has led to widespread adoption in a range of industrial sectors:

- Food Manufacturing: Ensuring uniformity in bulk ingredients for products such as spice blends, dry soups, and cake mixes helps maintain consistency in flavor and texture.

- Chemicals: Blending raw materials in the production of coatings, detergents, adhesives, and resins, where precise mixing is necessary for optimal chemical properties.

- Pharmaceuticals: Achieving a homogenous blend of active components and excipients, which is essential for patient safety and dosage accuracy.

- Construction Materials: Mixing powders and aggregates for materials such as concrete, mortars, and dry wall compounds, supporting robust construction practices.

Design Innovations in Paddle Blenders

Modern paddle blenders have evolved with the introduction of features such as fluidizing paddle agitators, which improve mixing speed by generating rapid yet gentle turbulence. This approach not only enhances mixing homogeneity but also reduces power requirements, leading to lower energy consumption. Advanced seals, improved accessibility for cleaning, and automated controls further boost operational reliability and workplace safety.

These innovations also respond to stricter industry regulations and consumer demand for higher safety and hygiene standards, particularly in sensitive sectors such as food, cosmetics, and pharmaceuticals. As a result, manufacturers can achieve higher throughput, improved batch repeatability, and compliance with stringent production protocols.

Choosing the Right Paddle Blender

Several factors should be considered when specifying a paddle blender for your operation:

- Production Volume: The blender’s capacity must align with your typical batch size for efficient operation.

- Material Properties: The blender’s geometry and paddle configuration should match the characteristics (flowability, particle size, cohesiveness) of your materials.

- Sanitization: Models that offer easy disassembly or CIP (Clean-in-Place) features are crucial when hygiene is a top priority.

- Power Consumption: Prioritize models with energy monitoring and efficiency certifications for long-term cost savings.

Maintenance and Safety Considerations

Regular preventative maintenance and adherence to safety guidelines are vital for extending the lifespan of paddle blenders and ensuring operator safety. Maintenance tasks should include scheduled inspections of bearings, seals, shafts, and paddles, as well as periodic replacement of high-wear components. Implementing lockout/tagout procedures mitigates the risk of accidents and supports compliance with occupational safety standards. Comprehensive staff training and thorough operational protocols contribute significantly to machine longevity and optimal output.

Conclusion

Paddle blenders have become indispensable for modern industrial processes due to their proven versatility, gentle mixing action, and operational efficiency. By carefully evaluating their production needs and understanding the latest technology and safety requirements, manufacturers can select paddle blenders that drive efficiency, quality, and long-term value in their operations.